Square plastic tubing refers to devices that offer a hollow path for moving gases, liquids, or granular or free-flowing materials. Plastic tubing is a practical solution for many industries and applications. Due to its square and non-cylindrical shape, it is easily distinguished from other tubes. Square tubing is easy to anchor, making it ideal for stationary devices. Read More…

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

At Crafted Plastics Inc., we have built our reputation on designing and producing high-quality plastic tubing that meets the needs of industries across the country. We take pride in offering precision-engineered tubing solutions that deliver consistency, durability, and performance in a wide range of applications. By working closely with our customers, we create tubing that not only meets exact...

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Pexco is a leading custom extruder of thermoplastic and elastomer tubing, fluoropolymer tubing and profiles, and heat-shrink and non-heat-shrink tubing. We offer tubing in a wide range of standard and custom sizes and colors in a multitude of material options like Polysulfone, PVC, Polyurethane, Nylon, and more. We use state-of-the-art machinery and perform secondary operations on site, such as...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

At Kent Rubber Supply Co., we take pride in delivering high-quality plastic tubing solutions that meet the diverse needs of our customers across multiple industries. As a trusted supplier and fabricator, we bring decades of experience in material selection, precision manufacturing, and custom assembly to every project we undertake.

More Square Plastic Tubing Manufacturers

Square Plastic Tubing: Manufacturing, Applications, and Buying Guide

How Square Plastic Tubing is Made

Square plastic tubing, also known as square PVC tubing or rectangular plastic tubing, is manufactured using advanced processes that ensure precision, durability, and consistency. The production process begins with defining the pipe dimensions and preparing specialized tube tooling. Two primary methods dominate square plastic tubing fabrication: plastic extrusion and cell casting.

Plastic Extrusion Process

The plastic extrusion process is the industry standard for producing square tubing due to its efficiency, scalability, and ability to create long, continuous lengths with uniform cross-sections. First, raw plastic material (often PVC, acrylic, or polyethylene) is gathered and placed into a hopper above a conveyance channel. Inside this channel, a rotating shearing screw, heating elements, and a die shape the material.

As the screw rotates, it generates heat and friction, gradually melting the plastic stock. The resultant molten plastic is forced through a die, specifically engineered to create the desired square or rectangular profile. Upon exiting the die, the extruded tube is rapidly cooled—usually through a water bath or air cooling system—ensuring dimensional stability. Once cooled, the tubing is cut to length and may proceed to additional finishing steps such as printing, drilling, or quality inspection.

Cell Casting Method

In the cell casting process, a liquid plastic resin is poured into a pre-shaped mold and allowed to solidify. This method is typically reserved for specialty tubing or custom sizes where precise tolerances and clarity are critical. Cell casting is ideal for applications requiring crystal-clear finishes or thicker wall sections beyond what extrusion can easily achieve. However, it is less efficient for mass production compared to extrusion.

Materials Used in Square Plastic Tubing

The selection of plastic materials used in the extrusion or casting process is crucial. Commonly used plastics include:

- PVC (Polyvinyl Chloride): Offers excellent chemical resistance, impact strength, and affordability.

- Acrylic (PMMA): Known for its optical clarity, rigidity, and weather resistance, making it ideal for displays and lighting.

- Polycarbonate: Provides superior impact resistance and transparency.

- Polypropylene: Lightweight, flexible, and highly resistant to chemical leaching.

- Polyethylene (HDPE & LDPE): Known for flexibility, toughness, and low cost.

- Nylon: High tensile strength and abrasion resistance.

- Polyurethane: Offers flexibility and excellent abrasion resistance.

Considering Environmental and Regulatory Factors

When selecting materials, it is important to factor in environmental compliance, such as RoHS and REACH standards, as well as specific industry regulations (for example, in medical or food-grade applications).

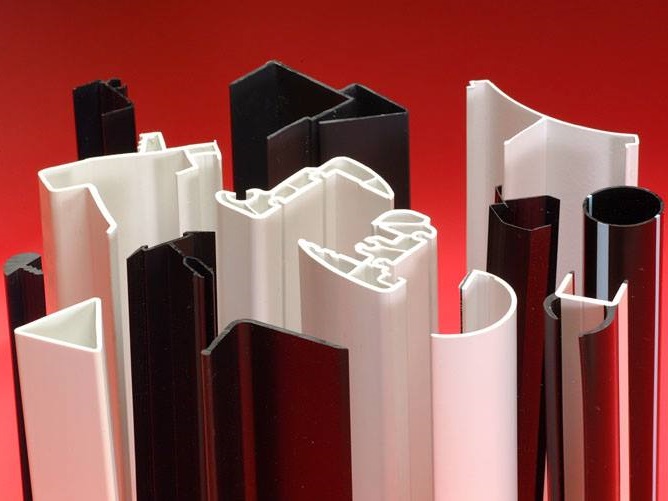

Types of Square Plastic Tubing

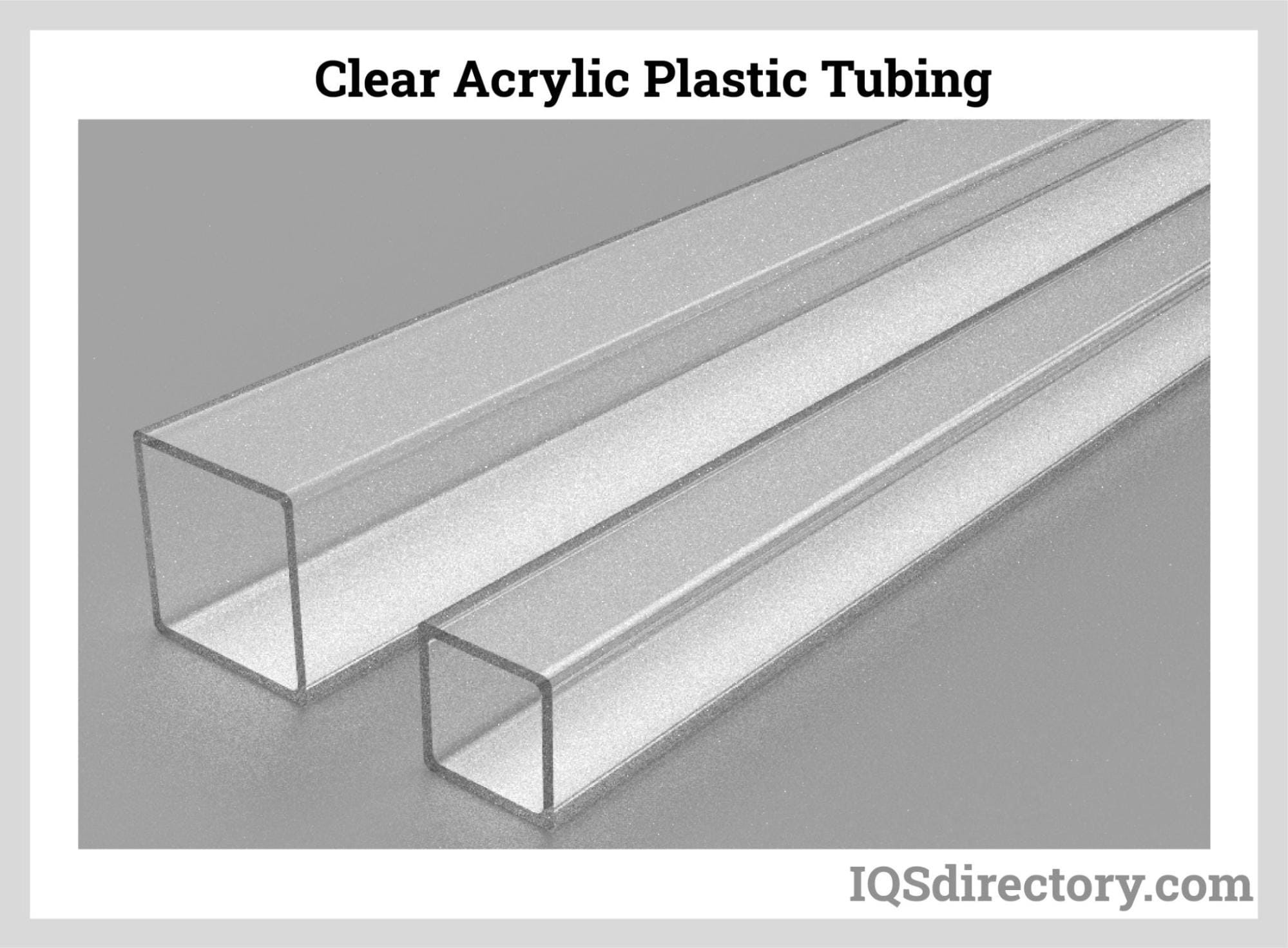

Clear Acrylic Plastic Square Tubing

Clear acrylic plastic square tubing is valued for its high transparency and polished surfaces. With smooth interiors and exteriors, it is frequently utilized in LED lighting fixtures, architectural displays, point-of-purchase stands, and laboratory equipment where visual monitoring of contents is needed. Acrylic’s UV resistance and aesthetic appeal make it a popular choice for both indoor and outdoor applications.

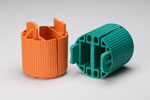

Two-Colour Coextrusion Plastic Square Tubing

Coextrusion technology allows manufacturers to combine two or more plastic materials or colors within a single extrusion process, resulting in two-color square plastic tubing. This method is ideal for creating tubing with enhanced mechanical properties—such as increased rigidity, flexibility, or heat resistance—and for products requiring color coding, branding, or aesthetic differentiation. Common applications include automotive trim, custom packaging, and signage.

Other Specialty Square Plastic Tubing Types

- Flexible square tubing: Used where routing around corners or vibration isolation is important.

- Colored and UV-stabilized tubing: For outdoor use or color-coding in industrial settings.

- Antimicrobial and food-safe tubing: For healthcare, food processing, and pharmaceutical applications.

- Heavy-wall square tubing: For structural or load-bearing installations.

Square Plastic Tubing in the Automotive Industry

The automotive sector is increasingly adopting square plastic tubing for lightweighting initiatives and innovative vehicle designs. Engineers are leveraging plastics’ inherent resistance to corrosion, chemical damage, and impact, as well as their flexibility for custom shapes. Square tubing is used in wiring harnesses, fuel and fluid lines, ventilation systems, and in custom 3D-printed interior and exterior components. Plastic tubing helps reduce vehicle weight, which can improve fuel efficiency, reduce emissions, and enhance overall vehicle performance.

With the rise of 3D printing and additive manufacturing, automakers can now produce bespoke plastic tubing solutions for prototypes and limited runs, optimizing space utilization and reducing time-to-market for new models. Recyclable plastics are also gaining favor, supporting sustainability and circular economy goals within the transportation industry.

Applications of Square Plastic Tubing

Square plastic tubing is recognized for its versatility and utility across diverse industries. Its unique profile and material properties make it an essential component in applications ranging from fluid transport to structural frameworks. Here are some of the most common and high-value uses for square plastic tubing:

- Medical and laboratory equipment: Used for fluid management, sample transfer, and as structural supports for diagnostic devices. Square tubing’s sterile, non-reactive surfaces are ideal where cleanliness is paramount.

- Architectural and construction: Frameworks for signage, partition walls, railing systems, and modern design elements leverage square tubing for its clean lines and customizable finishes.

- Industrial automation: Protects wiring, fluid conduits, and pneumatic systems in robotics and manufacturing equipment, with benefits such as corrosion resistance and easy installation.

- Retail and display: Supports shelving, showcases, and product displays, especially where aesthetics and transparency are key.

- Automotive and transportation: Employed in fuel systems, HVAC lines, and lightweight structural supports.

- Aquariums and water treatment: Used in filtration, aeration, and plumbing systems due to its resistance to chemicals and waterborne contaminants.

- DIY, hobby, and maker projects: Popular among makers for creating custom enclosures, frames, and craft structures.

Benefits of Square Plastic Tubing Over Alternative Materials

- Corrosion resistance: Unlike metal tubing, plastic does not rust or degrade in harsh environments.

- Lightweight: Easier to handle, transport, and install, reducing labor costs.

- Customizability: Available in a wide range of sizes, colors, and finishes to suit specific project requirements.

- Cost-effectiveness: Generally more affordable than metal or glass alternatives, especially for bulk orders.

- Hygienic and easy to clean: Vital for medical, laboratory, and food applications.

- Electrical insulation: Plastic tubing acts as a barrier for wiring and other sensitive components.

Commonly Used Plastic Tubing Materials and Their Strengths

HDPE (High-Density Polyethylene): Offers superior impact resistance and is widely used in industrial and environmental applications.

LDPE (Low-Density Polyethylene): Provides flexibility and is suitable for low-pressure fluid transport.

PVC (Polyvinyl Chloride): Popular for its balance of affordability, strength, and chemical resistance.

Polyurethane: Preferred in applications requiring abrasion resistance and flexibility.

What to Take into Account When Selecting Square Plastic Tubing

Choosing the right square plastic tubing for your project involves careful consideration of several factors. To help you make an informed decision, ask yourself the following questions:

- What is the intended application? (e.g., fluid transfer, structural support, display, insulation)

- What are the required dimensions and tolerances? (inner/outer diameter, wall thickness, length)

- Which plastic material best suits your environment? (temperature, chemical exposure, UV, food safety, regulatory compliance)

- What levels of clarity, color, or flexibility do you need?

- Are there industry-specific requirements? (e.g., FDA, NSF, RoHS, medical grade)

- Do you need custom fabrication or secondary operations? (drilling, notching, printing, bending)

It’s also crucial to assess the manufacturer’s quality control processes, delivery timelines, and ability to provide technical support or documentation (such as material data sheets or compliance certificates).

Comparing Square Plastic Tubing vs. Round Tubing

Square tubing offers distinct advantages in applications where flat surfaces, modular assembly, or flush mounting are required. However, round tubing may be preferred for high-pressure fluid transport or when minimizing weight is the top priority. Consider the following:

- Square tubing is easier to join with brackets, fasteners, and connectors.

- It provides greater stability in frameworks and shelving systems.

- Round tubing may offer better resistance to internal pressure and is often used for pneumatic or hydraulic systems.

Frequently Asked Questions About Square Plastic Tubing

- How do I cut or machine square plastic tubing? Most plastic tubing can be cut using standard woodworking tools (like a miter saw) or specialized plastic cutters. For precision work, CNC machining or laser cutting is recommended.

- Is square plastic tubing recyclable? Many plastics (like HDPE, LDPE, and certain grades of PVC and acrylic) are recyclable. Always check the recycling codes and local guidelines.

- Can square plastic tubing be sterilized? Yes, many plastics can be sterilized using autoclaving, chemical disinfection, or UV treatment—though always verify the material’s compatibility with your sterilization method.

- What is the maximum temperature square plastic tubing can withstand? This depends on the material—PVC typically handles up to 140°F (60°C), while polycarbonate and nylon can withstand higher temperatures.

- Are custom sizes or colors available? Most manufacturers offer custom extrusion services, allowing you to specify dimensions, wall thickness, color, and even integrate branding.

Choosing the Correct Square Plastic Tubing Company

To ensure you select the best square plastic tubing supplier for your needs, follow these steps:

- Compare at least five reputable companies using our square plastic tubing directory.

- Review each supplier’s business profile, focusing on their experience, materials expertise, and customization capabilities.

- Use the integrated contact form on each profile to request more information, product catalogs, or a quote tailored to your project.

- Preview each company’s website with our proprietary previewer to assess specialization, certifications, and previous projects.

- For bulk orders or complex applications, use our simple RFQ form to contact multiple suppliers simultaneously with your requirements.

Look for suppliers with a strong track record in your industry (such as medical, automotive, or construction), robust quality assurance programs, and the ability to provide technical guidance on material selection, compliance, and fabrication techniques. Don’t hesitate to ask about lead times, minimum order quantities, and after-sales support.

Ready to Find the Right Square Plastic Tubing?

Start your search for the perfect square plastic tubing by considering your application, material requirements, and budget. Use our directory to request quotes from leading suppliers, or contact our technical team for advice on choosing the most suitable tubing for your project.

Summary: Why Square Plastic Tubing is the Smart Choice

Square plastic tubing offers a unique combination of strength, lightness, and adaptability. Its corrosion resistance, ease of fabrication, and wide range of available materials and sizes make it a top choice for professionals in construction, medical, automotive, retail, and industrial sectors. By understanding manufacturing methods, material options, and the key factors in supplier selection, you can confidently choose tubing that meets your specifications and enhances your project’s success.

For more information or to start sourcing square plastic tubing, browse our supplier directory or reach out to our team for expert guidance.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services