Industrial hoses are a critical manufacturing tool used to transport fluids, connect machines, and supply high pressure air. The importance of industrial hoses necessitates that they be manufactured with precision, attention to detail, and compliance with hose parameters Read More…

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

At Crafted Plastics Inc., we have built our reputation on designing and producing high-quality plastic tubing that meets the needs of industries across the country. We take pride in offering precision-engineered tubing solutions that deliver consistency, durability, and performance in a wide range of applications. By working closely with our customers, we create tubing that not only meets exact...

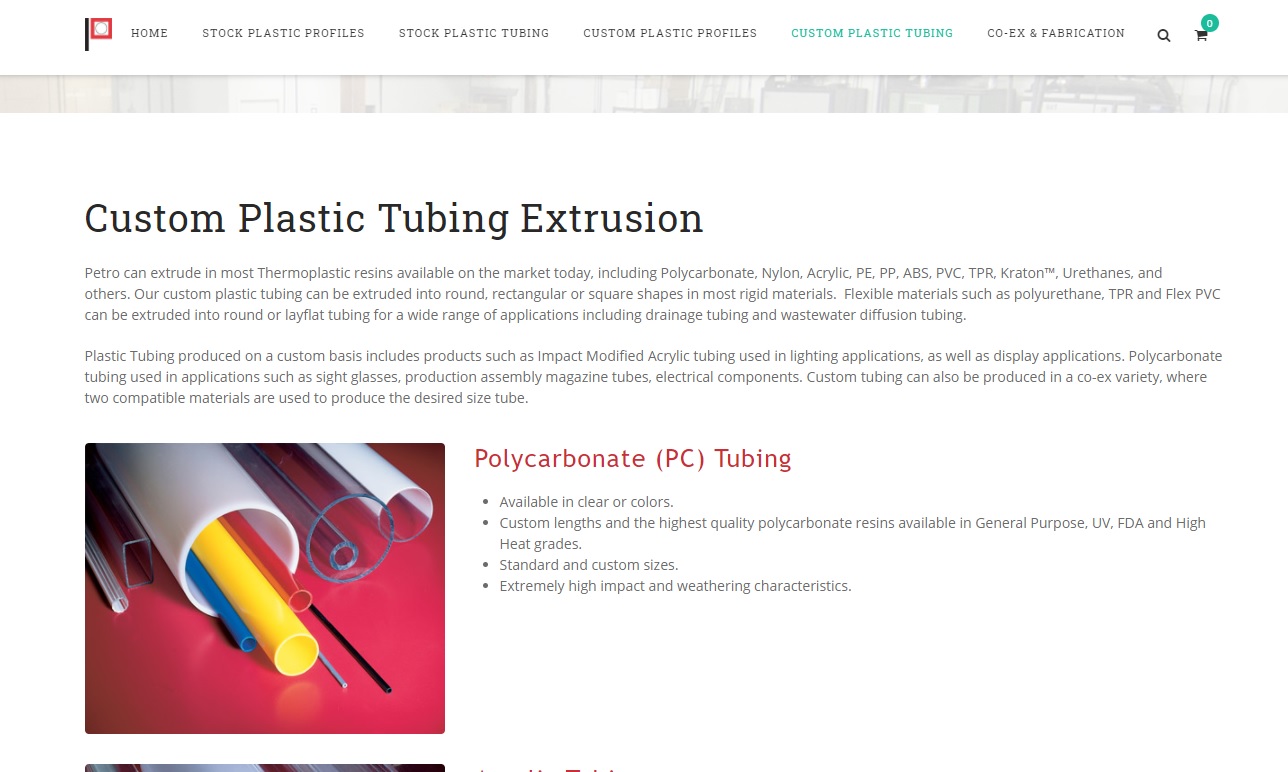

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Pexco is a leading custom extruder of thermoplastic and elastomer tubing, fluoropolymer tubing and profiles, and heat-shrink and non-heat-shrink tubing. We offer tubing in a wide range of standard and custom sizes and colors in a multitude of material options like Polysulfone, PVC, Polyurethane, Nylon, and more. We use state-of-the-art machinery and perform secondary operations on site, such as...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

At Kent Rubber Supply Co., we take pride in delivering high-quality plastic tubing solutions that meet the diverse needs of our customers across multiple industries. As a trusted supplier and fabricator, we bring decades of experience in material selection, precision manufacturing, and custom assembly to every project we undertake.

More Industrial Hose Manufacturers

The materials used to produce industrial hoses dictate their production method, which varies from extrusion to being spiral wrapped.

Regardless of the variations in production methods, all industrial hoses share the same basic components that are applied in layers and are necessary to ensure the durability and strength of an industrial hose. The properties that are required of all industrial hoses are endurance, durability, strength, toughness, and longevity. Unlike garden hoses and residential hoses, industrial hoses face harsh and stressful conditions that place an exceptional amount of demand on their structure.

Although industrial hose manufacturers produce all types of hoses from DIY hoses to chemical industry hoses, they put a great deal of effort, planning, and engineering into the production of industrial hoses. These measures are necessary due to the type of work industrial hoses perform and the importance of safety.

Components of Industrial Hoses

Each aspect of an industrial hose serves a specific purpose and is chosen to meet the standards established for a particular hose. The initial phase of industrial hose manufacturing is the selection of materials. The complexity of the selection process is complicated by the variations of materials used for each layer. Regardless of the type of industrial hose and its materials, all industrial hoses have layers, which are the inner layer or tube, reinforcement layer, and outer protective layer. The consistency of each layer varies in accordance with the materials an industrial hose is designed to transport.

Although there are three basic layers to all industrial hoses, additional adjustments may be added to each layer to further improve a hose’s stability and endurance. For example, the outer layer of a hose may be made of rubber that has been reinforced with wire mesh. Hoses for high temperature applications or firefighting have a fabric layer that is treated with fire retarding material, such as silicone. In most cases, the three basic layers remain consistent and uniform with adjustments to meet existing conditions.

Inner layer or Inner Tube

Since the inner layer comes in contact with the transported fluid, gas, or particles, it has to be compatible with the materials that pass through it. The inner layer is normally composed of some type of rubber, such as PKR, EPDM, or butyl rubbers. Petroleum and kerosene resistant rubber (PKR) is commonly used due to its ability to withstand the effects of petroleum products and its ability to endure harsh weather conditions. Ethylene propylene diene monomer (EPDM) is a polymer with exceptional resistance to high temperature liquids and its ability to handle fireproof hydraulic liquids.

The manufacture of the inner tube or inner layer varies in accordance with the type of material. Extrusion is commonly used due to its ability to produce high tolerance and dimensionally accurate tubing. Mandrel wrapping is ideal for large industrial hoses, which allows for multiple layers to be applied to an inner layer. As can be deduced, the size of an industrial hose also influences how its inner layer is manufactured.

Reinforcement Layer

The reinforcement layer of industrial hoses gives an industrial hose its strength and durability. It takes several forms depending on the type of industrial hose and, as with the inner layer, is applied in different forms. The reinforcement layer surrounds the inner layer and gives the inner layer and the hose resilience and durability. The key to the reinforcement layer is its structure, which can include a wide range of highly durable and long-lasting materials.

Depending on the use of an industrial hose, the reinforcement layer is generally made up of fibers, stainless steel, or certain forms of plastic. The styles of the reinforcement layer are spiral, coiled, helical, and braided. Coiled reinforcement layers are cost effective but are not sufficiently stable to last, especially for high pressure applications.

Braided reinforcement, which is a strong and durable reinforcement method, involves interweaving strands of material to form a flexible and strong reinforcement layer. The main characteristic and benefit of braided reinforcement is its ability to withstand the effects of internal pressure, while maintaining its flexibility. The three forms of braided reinforcement are single, double, and multilayered. The difference between the three is the strength that they provide with single braiding being moderately strong, while multilayer braiding provides exceptional durability, strength, and the ability to endure extreme pressure.

Spiral reinforcement involves wrapping wire around the inner layer in a helical pattern to provide strength and the ability to withstand extreme pressures. Its use includes very demanding and stressful applications. The construction of spiral reinforcement involves the application of multiple layers with each layer inserted in an alternate direction, which maximizes the strength of an industrial hose and prevents its expansion when exposed to high pressure.

Helical reinforcement is a construction technique that involves winding wire in a helical pattern to avoid kinking and crushing of a hose. During the winding process, wire is wound continuously to distribute it evenly and uniformly, such that the hose can maintain its flexibility. As with all types of industrial hoses, helical reinforced hoses can have single or multiple layers. The main characteristic of helical wound industrial hoses is their flexibility, which slightly deters from their strength.

Knitted reinforcement layers include the application of textile fibers that have been knitted to add strength. The properties of the chosen material determine the strength of an industrial hose. Although the technique involves knitting, the fabrics being knitted include various plastics that have superior strength. In addition, prior to being knitted, the fabrics may be treated with fire inhibitors for extra protection.

Regardless of the method used, the reinforcement layer is placed around the inner layer or tube and wrapped tightly to ensure a secure, uniform, and even connection to the inner layer. It is essential that the reinforcement layer be properly attached since it is the aspect of an industrial hose that determines a hose’s strength.

Outer Layer

The strength and durability of an industrial hose is provided by its reinforcement layer. It is designed to ensure a hose can endure the application for which it is designed. The outer layer serves as a wall of protection for the inner and reinforcement layers. It is designed to withstand the effects of external factors and environmental conditions. The materials chosen for the outer layer protect the reinforcement layer against moisture, dust, heat, rain, cold, abrasions, and impacts.

Aside from being a layer of protection, the outer layer of an industrial hose has a set of numbers and letters that identify various aspects of a hose, such as its pressure rating, part number, date of manufacture, and batch number. These identifiers assist manufacturers and customers with identifying a hose, the years of its use, its usable applications, and other factors. In many cases, the labeling of a hose is proprietary to its manufacturer to assist them in identifying any hose failures.

Final Note

The selection of an industrial hose is far from a trivial process due to the necessary safety and protective attributes that industrial hoses must possess. All industrial hose manufacturers work closely with clients in providing guidance and assistance in selecting the correct hose for an application. The essence of their interchange is the method of production, the materials used, and a hose’s structure. Customers provide data as to how a product will be used in regard to environmental conditions and the materials to be transported.

The collaboration between manufacturers and clients is an essential aspect of the successful use of a critical and essential manufacturing tool.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

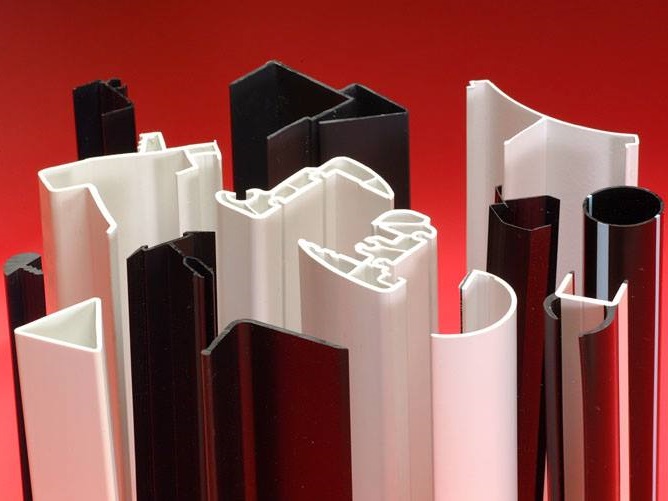

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services