Tubing is an extruded, non-reinforced cylinder of any size. Rigid plastic tubing is a form of plastic tubing that can be utilized in applications that need stiff and unbending tubing. Frequently, the tube must meet FDA, NSF, or UL specifications. Medical, plumbing, mining, gas transportation, and beverage industries use rigid plastic tubing. Read More…

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

At Crafted Plastics Inc., we have built our reputation on designing and producing high-quality plastic tubing that meets the needs of industries across the country. We take pride in offering precision-engineered tubing solutions that deliver consistency, durability, and performance in a wide range of applications. By working closely with our customers, we create tubing that not only meets exact...

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

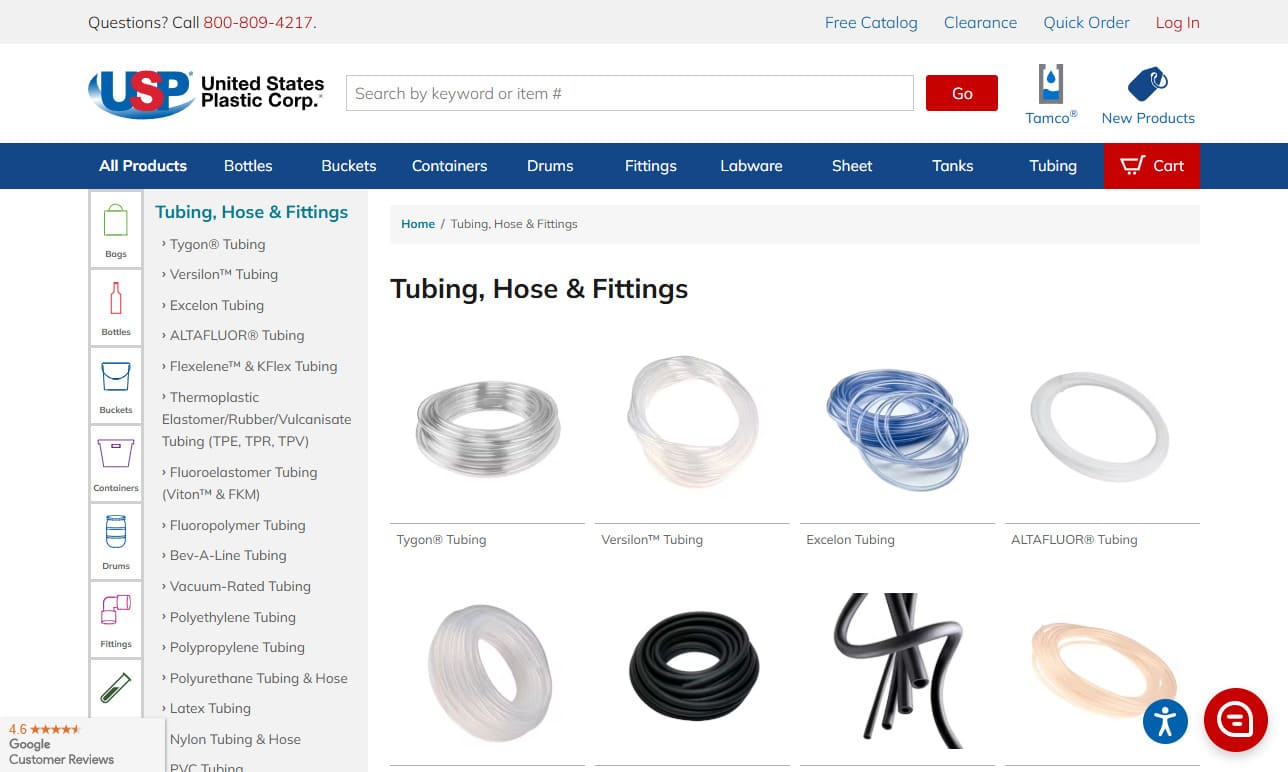

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Pexco is a leading custom extruder of thermoplastic and elastomer tubing, fluoropolymer tubing and profiles, and heat-shrink and non-heat-shrink tubing. We offer tubing in a wide range of standard and custom sizes and colors in a multitude of material options like Polysulfone, PVC, Polyurethane, Nylon, and more. We use state-of-the-art machinery and perform secondary operations on site, such as...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

At Kent Rubber Supply Co., we take pride in delivering high-quality plastic tubing solutions that meet the diverse needs of our customers across multiple industries. As a trusted supplier and fabricator, we bring decades of experience in material selection, precision manufacturing, and custom assembly to every project we undertake.

More Rigid Plastic Tubing Manufacturers

Rigid Plastic Tubing: Manufacturing, Applications, and Selection Guide

What is Rigid Plastic Tubing?

Rigid plastic tubing is a highly durable, chemically resistant solution widely used for transporting fluids, gases, and solids in industrial, commercial, and residential settings. Known for its structural integrity and adaptability, rigid plastic tubing is manufactured in a variety of shapes, sizes, and materials to meet a broad array of application requirements. Whether you’re seeking hard plastic tubing for plumbing, medical, food and beverage, or laboratory uses, understanding the benefits, manufacturing processes, and selection criteria can help guide your purchasing decision.

How Rigid Plastic Tubing is Made

Modern rigid plastic tubing is manufactured from a selection of high-performance polymers, each offering unique attributes suited to specific environments. Common materials used to produce rigid tubing include ABS (Acrylonitrile Butadiene Styrene), CABS (Cellulose Acetate Butyrate), PVDF (Polyvinylidene Fluoride), PET polyester, polypropylene (PP), high-density polyethylene (HDPE), polyvinyl chloride (PVC), polystyrene crystal, acrylic (PMMA), and stiff polyvinyl chloride.

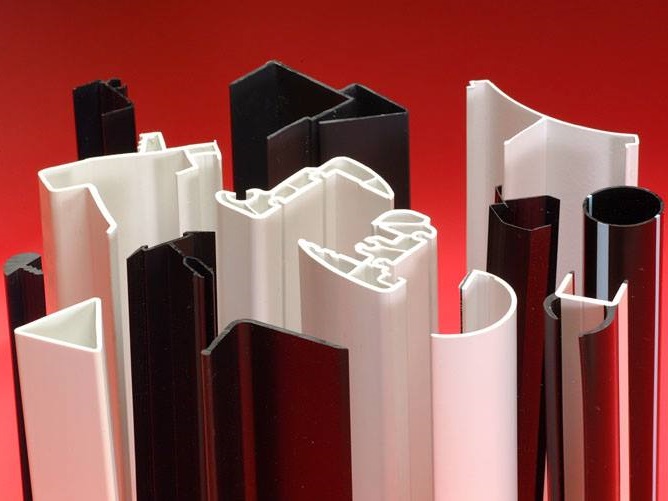

These materials are classified as thermoplastics. Thermoplastics are polymers that become pliable or moldable above a specific temperature and solidify upon cooling, enabling manufacturers to melt and remold the plastic repeatedly without degrading its molecular structure. This property is crucial for forming rigid plastic tubing into precise, consistent shapes through extrusion or injection molding techniques. Tubes can be produced in a range of cross-sections, including round, oval, triangular, rectangular, square, and custom (bespoke) profiles, to suit diverse use cases.

Key Manufacturing Processes for Rigid Tubing

- Extrusion: The primary method for producing long, continuous lengths of rigid plastic tube, in which melted thermoplastic is forced through a die that shapes the tubing.

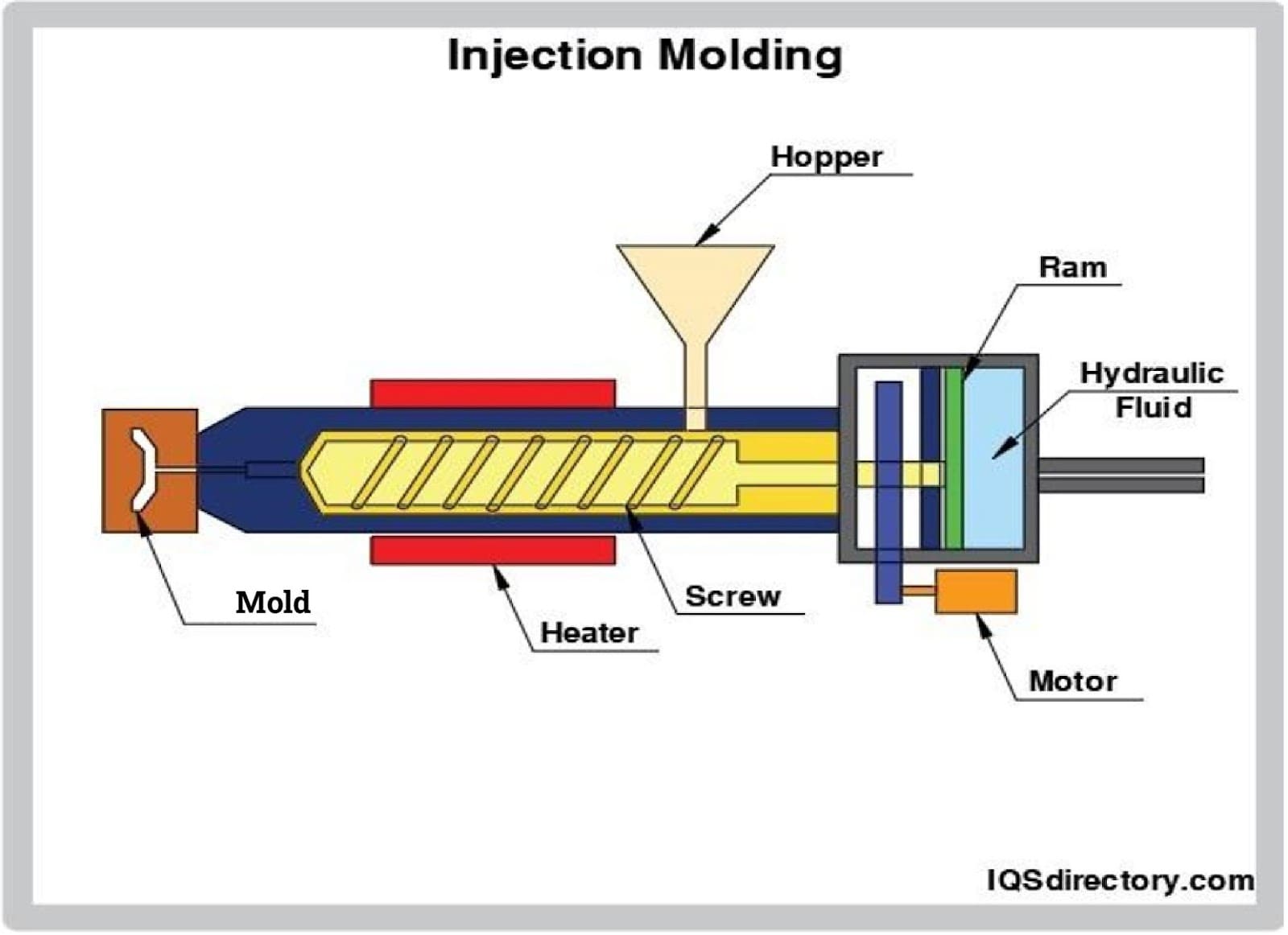

- Injection Molding: Used for manufacturing complex or precision-shaped tube fittings and components, where molten plastic is injected into a mold cavity and then cooled.

- Cutting & Finishing: Post-extrusion, rigid tubing can be drilled, cut, machined, stamped, bent, or joined to other pieces as per application requirements.

Looking for the Best Rigid Plastic Tubing Material?

Not sure which material suits your application? See our detailed guide below to compare the chemical resistance, temperature tolerance, and physical properties of common rigid plastic tubing materials.

Semi-Rigid Plastic Tubing: Features and Uses

Semi-rigid plastic tubing bridges the gap between rigid and flexible tubing options. It offers exceptional durability, lightweight construction, and resilience against abrasion, crushing, and cracking. These features make semi-rigid tubing a go-to choice for fluid transfer systems where flexibility and long-term integrity are essential.

- Resistant to flexural fatigue, tube vibration, and repeated movement

- Large bend radius minimizes kinking and flow restriction

- Absorbs minimal moisture, preventing swelling or deterioration in humid or wet environments

Semi-rigid tubing is available in the same array of extruded shapes as rigid tubing: round, oval, triangular, rectangular, and square. This versatility enables seamless integration into existing systems or custom applications.

Where is Semi-Rigid Plastic Tubing Used?

- Medical fluid delivery systems

- Automotive fuel and vacuum lines

- Food and beverage dispensing equipment

- Industrial pneumatic and hydraulic systems

- Aquarium and water treatment setups

Searching for the Right Tube for Your Application?

Explore our semi-rigid plastic tubing selection to compare diameters, wall thicknesses, and resistance ratings.

Benefits of Using Rigid Plastic Tubing

- Lightweight and Strong: Rigid plastic tubing combines low weight with high tensile and impact strength, making it easier and cheaper to transport, handle, and install compared to traditional metal pipes.

- Corrosion and Chemical Resistance: Unlike metal, plastic tubing resists corrosion, pitting, rust, and chemical attack, extending operational life in harsh environments.

- Sanitary and Hygienic: Plastic is inherently resistant to fungus, mold, and bacterial growth. This makes rigid plastic tubing ideal for potable water delivery, pharmaceutical manufacturing, and food processing.

- Flexibility Under Load: While rigid, these tubes often retain enough flexibility to accommodate minor earth movements or settlement, especially valuable in earthquake-prone or unstable regions.

- Cost-Effective Installation: Due to their ease of cutting, joining, and shaping, rigid plastic tubes require less specialized labor and fewer joints, reducing both installation time and total project costs.

- Smooth Internal Surfaces: The non-porous, flat internal surface of plastic tubing minimizes flow resistance and inhibits scale buildup, ensuring efficient long-distance liquid transfer and reducing maintenance costs.

- Inert and Stable: These materials are chemically inert, ensuring safe transport of aggressive chemicals without risk of leaching or contamination.

- Customizability: Plastic tubes can be produced in a vast range of diameters, wall thicknesses, and colors, with clear, translucent, and opaque options available for application-specific needs.

Why Choose Rigid Plastic Tubing Over Metal or Flexible Alternatives?

Plastic tubing outperforms many traditional materials in terms of cost, chemical compatibility, installation speed, and longevity. Curious about how rigid plastic compares to copper, steel, or flexible tubing? Read our in-depth comparison guide.

Applications of Rigid Plastic Tubing

Plastic tubing is engineered for outstanding versatility and performance, serving critical roles in various industries. Its hollow construction makes it suitable for transporting liquids, air, or solids. Tubing can be manufactured with different bend radii (flexibility), chemical resistance, wall thickness, durometer hardness, and temperature and pressure ratings to meet specific system requirements.

Common Rigid Plastic Tubing Applications

- Beverage Tubing: Used for dispensing, brewing, and bottling lines due to sanitary properties and easy cleaning.

- Cores and Dip Tubes: Essential in packaging, industrial fluid transfer, and laboratory setups.

- Feeder and Filtration Tubes: Integrated into irrigation, aquaculture, and water filtration systems for long-lasting performance.

- Medical and Laboratory Tubing: Manufactured under strict standards for purity and biocompatibility, ensuring safe fluid transfer for diagnostic and therapeutic processes.

- Packaging and Shipping Tubes: Protects products in transit and storage, offering customizable lengths and wall strengths for different weights and sizes.

- Structural and Decorative Uses: Rigid tubes serve as lightweight structural elements or as aesthetic coverings in construction, retail, and display applications.

- Automotive and Aerospace: Used in fuel, air, coolant, and hydraulic systems where durability and chemical resistance are crucial.

- Electrical Conduit: Shields wires and cables in commercial and industrial facilities from physical damage and environmental exposure.

Color and Finish Options for Rigid Tubing

Rigid plastic tubing is available in clear, translucent, and opaque finishes, with a wide variety of colors to facilitate identification, regulation, and system organization. For instance, clear tubing is essential in applications requiring visual monitoring of fluid flow, while opaque or colored tubes are better for protecting sensitive contents or distinguishing between different lines. Multi-colored options can be used for decoration, safety signaling, or branding. Tubing can also be finished in high-gloss or matte surfaces, and tailored with a range of wall thicknesses to suit mechanical and aesthetic requirements.

Can Rigid Plastic Tubing Be Customized?

Absolutely. Rigid plastic tubing can be drilled, machined, stamped, bent, and joined to other tubes or fittings, supporting custom fabrication for unique projects or OEM needs. Explore custom rigid plastic tubing options for sizes, shapes, and performance requirements outside standard specifications.

Choosing the Right Rigid Plastic Tubing Material

Selecting the best rigid plastic tubing for your project involves evaluating several material properties and application-specific factors. Here are some key decision criteria to help you compare options and select the optimal tubing for your needs:

- Chemical Compatibility: Does your application involve acids, bases, solvents, or other aggressive chemicals? Materials like PVDF and polypropylene offer superior chemical resistance, while PVC and PET are ideal for neutral or potable water systems.

- Temperature Range: Consider both the operating and ambient temperature. For high-temperature environments, choose tubing made from PVDF, PET, or HDPE. For cold climates, polypropylene and PVC maintain flexibility and impact resistance.

- Pressure Rating: Ensure the tube’s wall thickness and material grade can safely handle your system’s pressure requirements.

- Certifications and Regulatory Compliance: Applications in food processing, medical, or potable water systems may require tubing certified to FDA, NSF, or USP standards.

- Transparency and Color Coding: Clear tubing is vital for visual inspection, while colored or opaque tubing aids in line identification and safety.

- Mechanical Properties: Evaluate the tube’s resistance to abrasion, crushing, UV exposure, and flexural fatigue, depending on installation and operational conditions.

- Cost and Availability: Balance your performance needs with budgetary constraints and consider lead times for custom or specialty tubing.

Need Help Selecting the Right Material?

Contact our material experts for recommendations based on your specific project requirements, or use our online RFQ tool to request samples and pricing.

Rigid Plastic Tubing vs. Metal and Flexible Tubing: Which is Right for You?

When evaluating tubing options, you may wonder how rigid plastic tubing compares to metal or flexible alternatives. Here’s a quick breakdown to guide your selection:

- Weight: Rigid plastic tubes are significantly lighter than metal pipes, reducing shipping and installation costs.

- Corrosion Resistance: Plastic does not rust or corrode, making it ideal for aggressive or humid environments where metal would fail.

- Chemical Compatibility: Many plastics outperform metals in resisting acids, alkalis, and solvents.

- Cost: Both material and installation costs for plastic are typically lower than for metal.

- Flexibility: Flexible tubing is better for tight bends or moving connections, but lacks the structural integrity and pressure handling of rigid tubing.

- Durability: Rigid tubing is more impact-resistant than flexible alternatives, especially in applications with high mechanical stress.

- Sanitation: Plastic’s non-porous surface resists biofilm and bacterial growth better than most metals.

Still unsure which tubing type fits your system? Compare all tubing types here or ask our technical team for advice.

Choosing the Right Rigid Plastic Tubing Manufacturer

Purchasing high-quality rigid plastic tubing requires careful evaluation of manufacturers and their capabilities. To ensure you make an informed choice, compare at least 4 to 5 companies from our rigid plastic tubing manufacturer directory. Each manufacturer profile includes information on areas of expertise, production capabilities, certifications, and material options.

Key steps to selecting a reliable rigid plastic tubing supplier:

- Review company profiles and product specifications

- Assess compliance with relevant industry standards (e.g., ISO, FDA, NSF, USP)

- Request product samples and technical data sheets

- Check lead times, minimum order quantities, and logistics options

- Compare pricing, warranty, and after-sales support

- Use our RFQ form to contact multiple suppliers simultaneously with your requirements

Our website previewer allows you to explore each company’s website quickly, helping you identify which manufacturers specialize in your required tube sizes, materials, and certifications. You can then use our simple RFQ tool to request quotes or further information from several suppliers at once.

Frequently Asked Questions About Rigid Plastic Tubing

What is the maximum temperature rigid plastic tubing can handle?

The temperature resistance depends on the material: for example, PVDF can handle up to 150°C (302°F), while PVC is suitable up to 60°C (140°F). Always consult material data sheets for specific ratings.

Can rigid plastic tubing be used for potable water?

Yes, many rigid plastic tubes (such as PVC, HDPE, and polypropylene) are certified for drinking water. Look for NSF or FDA approval for potable water applications.

Is rigid plastic tubing UV-resistant?

Certain materials like acrylic and specific grades of PVC offer good UV stability. For outdoor use, ensure your tubing is UV-resistant or consider protective coatings.

How do I determine the right size and wall thickness?

Base your decision on the required flow rates, pressure ratings, and compatibility with fittings. Use our tubing sizing guide for detailed calculations.

Can I order custom lengths or colors?

Most manufacturers offer custom fabrication to meet your exact length, diameter, wall thickness, and color needs. Learn more about custom tubing options here.

Get Expert Help with Your Rigid Plastic Tubing Project

Ready to select, specify, or purchase rigid plastic tubing for your application? Request a quote from top manufacturers, or contact our technical team for fast, expert guidance. We’re here to help you find the best solution for your fluid handling, structural, or specialty tubing needs—no matter your industry or project complexity.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services