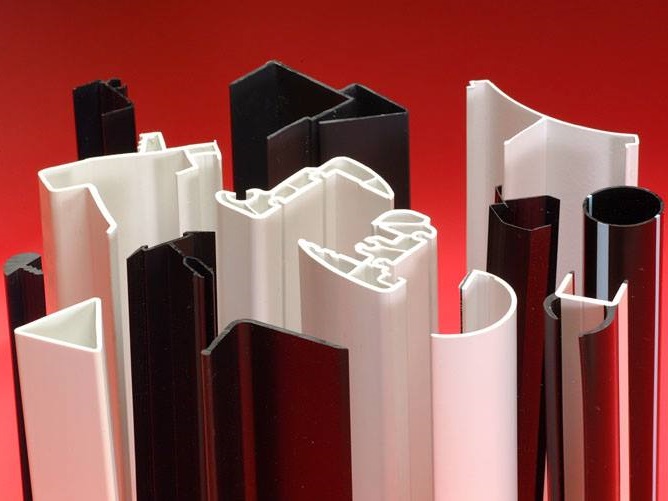

Plastic compounds are used to make clear, translucent, opaque, or multi-colored thin wall plastic tubing. Thin wall plastic tubing is mostly utilized in packaging, packaging enhancement, and as an overwrap. It is extruded in various grades and compositions to suit regulatory requirements for custom applications. Read More…

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

At Crafted Plastics Inc., we have built our reputation on designing and producing high-quality plastic tubing that meets the needs of industries across the country. We take pride in offering precision-engineered tubing solutions that deliver consistency, durability, and performance in a wide range of applications. By working closely with our customers, we create tubing that not only meets exact...

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Pexco is a leading custom extruder of thermoplastic and elastomer tubing, fluoropolymer tubing and profiles, and heat-shrink and non-heat-shrink tubing. We offer tubing in a wide range of standard and custom sizes and colors in a multitude of material options like Polysulfone, PVC, Polyurethane, Nylon, and more. We use state-of-the-art machinery and perform secondary operations on site, such as...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

At Kent Rubber Supply Co., we take pride in delivering high-quality plastic tubing solutions that meet the diverse needs of our customers across multiple industries. As a trusted supplier and fabricator, we bring decades of experience in material selection, precision manufacturing, and custom assembly to every project we undertake.

More Thin Wall Plastic Tubing Manufacturers

Thin Wall Plastic Tubing: Manufacturing, Grades, Applications, and Supplier Selection

Thin wall plastic tubing is a versatile and cost-effective solution across numerous industries, offering lightweight, durable, and highly customizable options for fluid transfer, packaging, medical devices, and more. In this comprehensive guide, we’ll explore the production methods, material grades, industrial and commercial uses, and key considerations when choosing a thin wall plastic tubing supplier. Whether you’re seeking information on custom plastic tubing, flexible tubing, or industry-specific requirements, this resource is designed to help you make informed decisions and find the best plastic tubing for your application.

How Thin Wall Plastic Tubing is Made

Modern thin wall plastic tubing is manufactured using advanced technologies that ensure precise dimensions, chemical compatibility, and performance tailored to diverse industry needs. The primary manufacturing processes include tube rolling and extrusion, each offering unique benefits for different use cases.

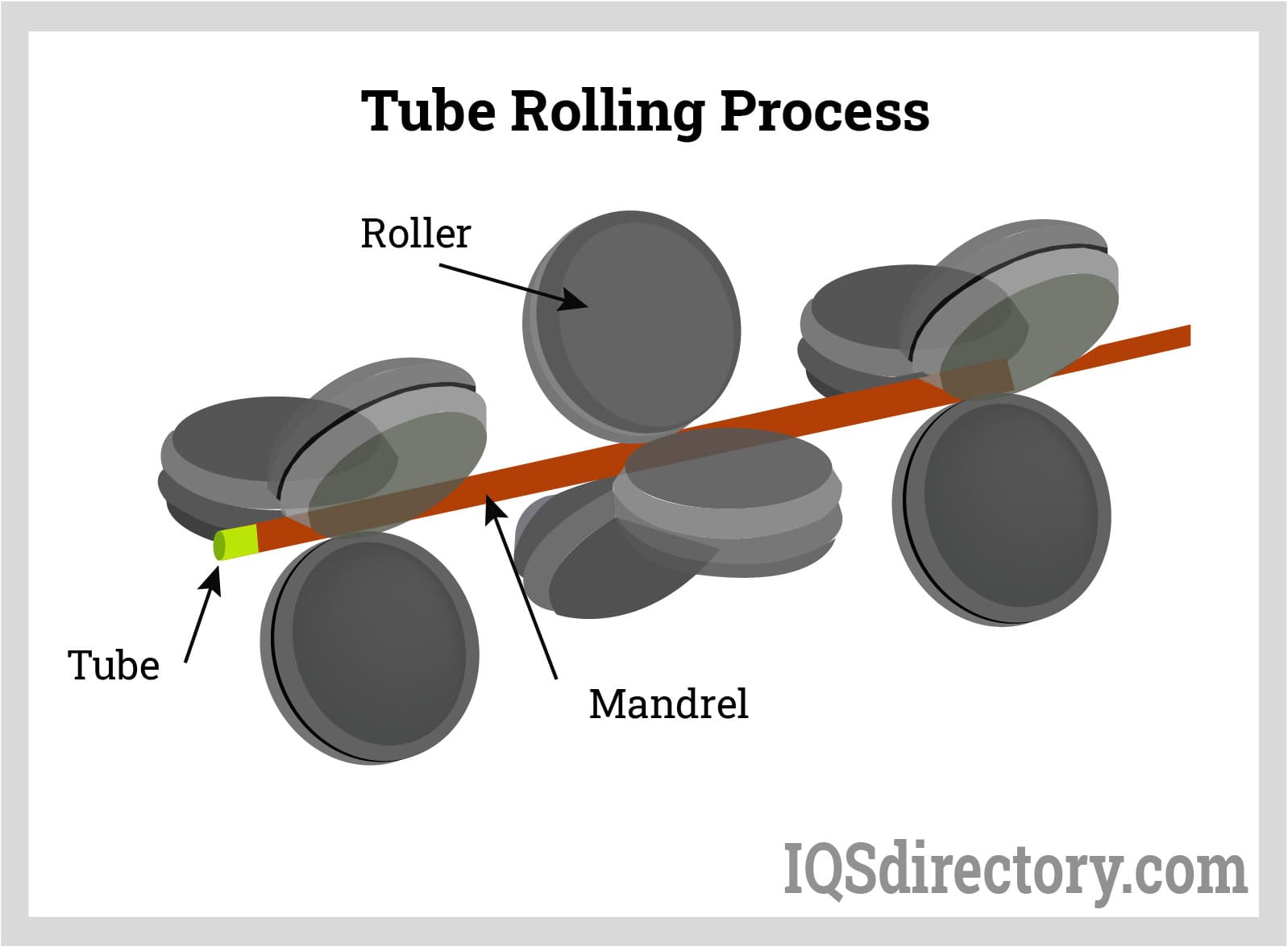

Tube Rolling Process

The tube rolling process begins by cutting pre-infused materials, such as specialty polymers or thermoplastics, and carefully rolling them around a cylindrical mold. To prevent air entrapment and ensure uniform wall thickness, the mold is often wrapped in a sleeve and subjected to controlled heat. This combination of pressure and temperature is critical for fusing the material layers and achieving the desired tube integrity.

Once the material has set, the mold is extracted, revealing a thin-walled, hollow tube that maintains tight tolerances and exceptional roundness. This meticulous process is ideal for custom thin wall tubing applications where precision, strength, and specific material properties are essential, such as in aerospace, laboratory, or certain medical device manufacturing. While tube rolling offers unmatched accuracy, it is generally more resource-intensive and suited for specialized, high-value projects.

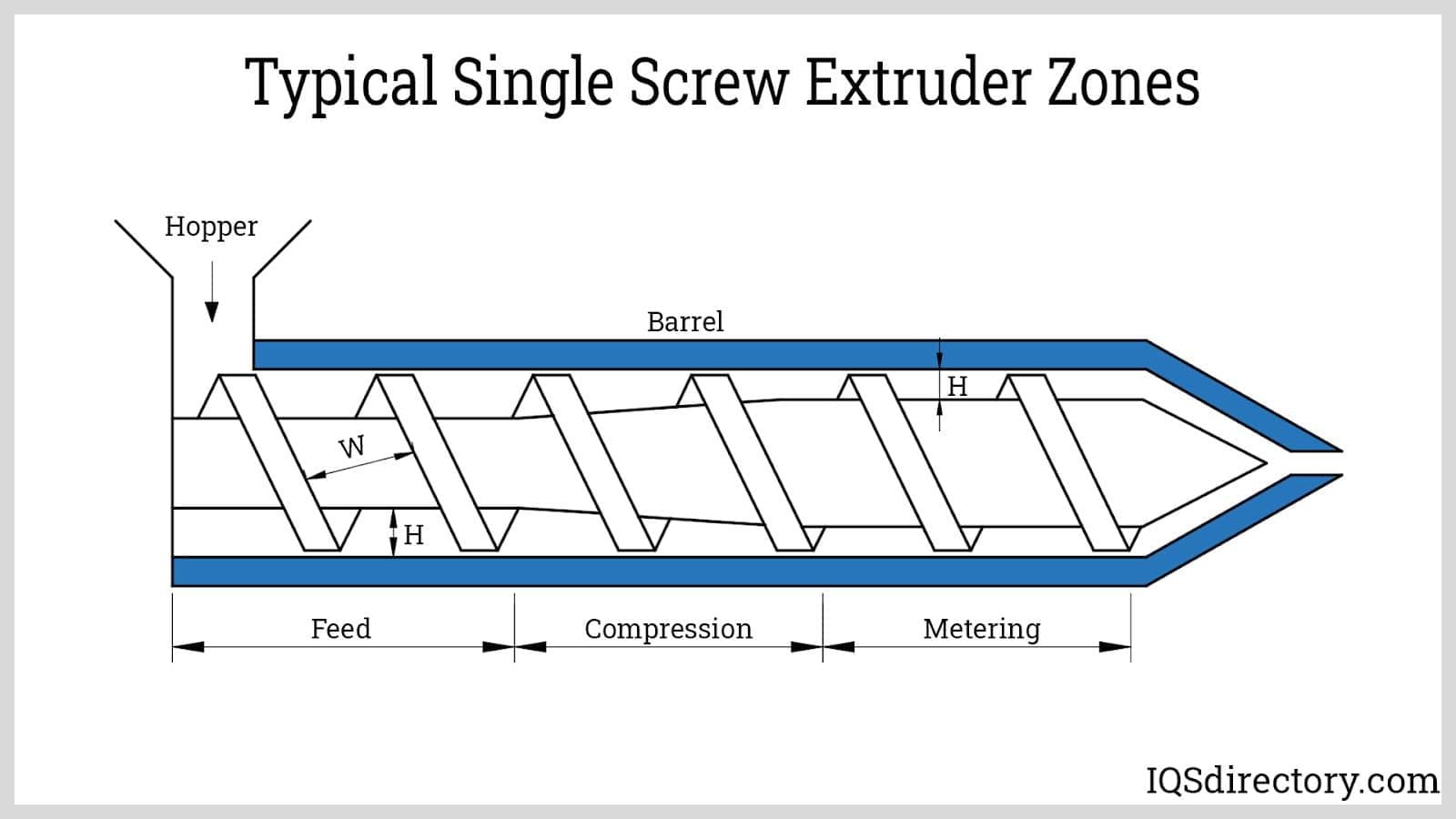

Extrusion Process

Plastic tube extrusion is the most prevalent and cost-efficient method for producing thin wall plastic tubing in large quantities. In this continuous process, raw polymer pellets—such as polyethylene (PE), polyvinyl chloride (PVC), or polyurethane (PU)—are melted and forced through a die shaped to the desired tube dimensions. The high temperature softens the material, enabling it to flow seamlessly into the die cavity, where it forms a consistent, hollow tube with precise wall thickness.

Depending on the extrusion approach (direct or indirect), the die remains stationary while material is either pushed or drawn through it, producing tubing that can be cut to custom lengths. The extrusion process allows for the integration of additives such as UV stabilizers, colorants, anti-microbial agents, or flame retardants, further enhancing the tubing’s properties and expanding its applications. This method is ideal for high-volume production of flexible or rigid thin wall tubing used in packaging, medical, and industrial fluid transfer.

Quality Control and Customization in Tubing Manufacturing

Quality control is paramount in thin wall plastic tubing production. Manufacturers use advanced measurement tools and in-line inspection systems to monitor wall thickness, diameter, ovality, and surface finish. This ensures that each batch meets stringent industry standards such as ISO 9001, FDA, USP Class VI, or NSF. Customization options include choosing specific polymers, wall thicknesses (from sub-millimeter to several millimeters), inner/outer diameters, clarity, color, and surface texture to fit unique project requirements.

Grades and Materials Used in Thin Wall Plastic Tubing

Choosing the right grade and material for thin wall plastic tubing is crucial for ensuring compatibility with your application’s demands. Manufacturers offer a wide range of tubing grades designed to meet regulatory, safety, and performance requirements across different industries.

Common Grades of Thin Wall Plastic Tubing

- FDA Grade Tubing: Designed for food, beverage, and pharmaceutical applications, FDA-compliant plastic tubing is formulated from materials that meet strict purity and safety standards.

- Flame Retardant Tubing: Used in environments where fire resistance is critical, such as electronics, automotive, and construction. These grades often comply with UL 94 or other relevant standards.

- Medical and Biocompatible Tubing: Manufactured to meet USP Class VI or ISO 10993 standards for use in medical devices, lab equipment, or drug delivery systems. These grades may feature anti-microbial or low-extractable properties.

- UV Stabilized Tubing: Enhanced with additives to resist degradation from sunlight, making it suitable for outdoor or high-exposure applications.

- Custom Formulations: Specialty grades are available for unique requirements, including high-pressure, low-temperature, chemically resistant, or anti-static tubing.

Popular Materials for Thin Wall Tubing

- Polyethylene (PE): Known for its flexibility, chemical resistance, and low cost. Common in beverage lines, irrigation, and wire insulation.

- Polyvinyl Chloride (PVC): Offers excellent clarity, strength, and versatility. Used for medical devices, laboratory tubing, and fluid transfer.

- Polyurethane (PU): Highly flexible, abrasion-resistant, and ideal for pneumatic control systems and robotics.

- Polypropylene (PP): Withstands high temperatures and aggressive chemicals. Used in laboratory and industrial settings.

- Polycarbonate (PC): Provides high impact resistance and transparency, suitable for critical fluid transport.

- Polyethylene Terephthalate Glycol (PETG): Offers excellent clarity and chemical resistance, making it ideal for packaging and display tubing.

- High Impact Polystyrene (HIPS): Used where cost and rigidity are primary concerns.

Depending on your project requirements, tubing can be produced as either rigid or flexible, transparent or opaque, and in custom colors or finishes. Not sure which material is right for you? Ask: What is the best plastic tubing material for my application? Explore more on plastic tubing materials.

Applications and Advantages of Thin Wall Plastic Tubing

Thin wall plastic tubing serves a broad spectrum of industries and is engineered to deliver specific advantages, such as low weight, chemical resistance, and ease of fabrication. Understanding your application’s needs helps you select the best tubing solution for your project.

Key Applications of Thin Wall Plastic Tubing

- Packaging: Used for crafts, toys, posters, food and confectionery items, baked goods, cosmetics, and personal care products. Its clarity and lightweight nature offer cost-effective, attractive presentation and protection for retail goods.

- Medical and Pharmaceutical: Thin wall tubing is crucial in medical device manufacturing, including catheter tubing, IV lines, fluid delivery systems, and laboratory sampling. It meets biocompatibility and sterilization requirements, ensuring patient safety.

- Industrial Fluid Transfer: Used for transporting chemicals, gases, and liquids in processing plants, water treatment, and pneumatic equipment. The precise wall thickness and material compatibility minimize leaks and contamination.

- Electronics and Electrical Insulation: Serves as insulation sleeves, protective conduits, and wire covers in consumer electronics, automotive harnesses, and industrial automation.

- Construction and HVAC: Provides lightweight, corrosion-resistant alternatives to metal piping for low-pressure air, water, and vent lines.

- Research and Laboratory: Utilized for sampling, dispensing, and transferring fluids in analytical and scientific settings.

- Outdoor and Agricultural Applications: UV-stabilized plastic tubing is employed in irrigation systems, greenhouse plumbing, and landscaping where sunlight exposure is significant.

Advantages of Thin Wall Plastic Tubing

- Lightweight and Flexible: Easy to install and route, reducing labor costs and simplifying system design. Flexibility reduces the need for fittings and welds, lowering leak risks and improving cleanliness in fluid transport systems.

- Chemical and Corrosion Resistance: Certain plastics resist a wide range of chemicals, acids, and solvents, making them ideal for aggressive environments where metal tubing would degrade.

- Cost-Effective: Lower material and installation costs compared to metal or glass alternatives. High-speed extrusion processes enable competitive pricing for large-scale projects.

- Precise, Consistent Dimensions: Advanced manufacturing processes deliver tubing with tight tolerances, minimizing variation and ensuring reliable system performance.

- Customizability: Tubing can be tailored in diameter, wall thickness, color, length, and formulation to meet unique project requirements or branding needs.

- Compliance and Safety: Grades are available that meet FDA, USP, UL, and NSF standards for regulated industries.

- Thermal and Electrical Insulation: Many plastics offer inherent thermal and electrical insulating properties, providing added safety in sensitive applications.

- Minimal Heat Loss: Low thermal conductivity preserves fluid temperature, which is critical in laboratory, medical, and industrial processes.

Thin Wall Plastic Tubing in Medical Applications

In the medical field, thin wall plastic tubing is indispensable for delivering fluids, gases, and medications with precision and safety. Medical-grade tubing is engineered to meet strict biocompatibility and sterilization standards, such as USP Class VI and ISO 10993. Common uses include IV tubing, catheters, peristaltic pump tubing, and protective sheaths for surgical instruments.

Choosing the right medical tubing involves evaluating flexibility, clarity, resistance to kinking, and compatibility with sterilization methods (gamma, autoclave, or EtO). For more details, read our dedicated guide on medical tubing applications.

Innovative Applications: Where is Thin Wall Plastic Tubing Used?

- How is thin wall plastic tubing used in emerging industries like renewable energy, biotechnology, or advanced manufacturing?

- What are the benefits of using clear plastic tubing in display or lighting installations?

- Can custom thin wall tubing be engineered for high-pressure or high-temperature environments?

Have a unique application in mind? Contact our team to discuss custom thin wall plastic tubing solutions tailored to your industry.

Factors to Consider When Selecting Thin Wall Plastic Tubing

When researching or specifying thin wall plastic tubing, it’s important to consider several factors to ensure optimal performance, safety, and compliance with regulatory requirements. Here’s a checklist to guide your selection process:

- Material Compatibility: Will the tubing withstand the chemicals, temperatures, and pressures in your application? Reference chemical resistance charts and supplier technical data sheets.

- Regulatory Compliance: Does your project require FDA, USP, NSF, RoHS, or REACH certification? Specify the standards your tubing must meet.

- Mechanical Properties: Evaluate flexibility, tensile strength, burst pressure, and impact resistance based on your system needs.

- Clarity and Color: Is visual monitoring of fluids important? Opt for clear tubing or request custom color options for identification.

- Size and Tolerance: Define inner and outer diameters, wall thickness, and length tolerances. Precision is critical in medical, laboratory, and automated manufacturing settings.

- Sterilization and Cleanliness: For medical and food applications, ensure the tubing can be sterilized by your chosen method and meets cleanliness requirements.

- Cost and Lead Time: Balance quality, customization, and delivery timelines to meet project budgets and schedules.

Looking for expert advice? Ask: What are the key considerations for selecting thin wall plastic tubing for my industry? Explore more about tubing applications.

Choosing the Proper Thin Wall Plastic Tubing Supplier

Partnering with the right thin wall plastic tubing supplier is essential for project success. Quality, customization capabilities, industry expertise, and customer service can vary widely between manufacturers. Here’s how to ensure you select the best supplier for your needs:

- Compare at least 5 suppliers to assess their experience, certifications, and product range. Use our curated list of thin wall plastic tubing suppliers as a starting point.

- Review each supplier’s business profile, which details their capabilities, areas of expertise, and history of serving specific industries (medical, industrial, packaging, etc.).

- Leverage our proprietary website previewer to quickly evaluate company websites for product details, manufacturing technologies, and customer testimonials.

- Use our streamlined RFQ (Request for Quote) form to contact multiple suppliers simultaneously, saving time and ensuring you receive competitive pricing and lead times.

- Consider value-added services, such as custom extrusion, secondary operations (cutting, drilling, printing), assembly, or inventory management, which can streamline your supply chain.

- Ask about quality assurance processes, traceability, and compliance documentation, especially if your project requires regulatory or industry certifications.

- Inquire about minimum order quantities, sample availability, technical support, and after-sales service.

Ready to source thin wall plastic tubing for your next project? Request quotes from leading suppliers and compare their capabilities to find the perfect fit for your application.

Frequently Asked Questions (FAQs) About Thin Wall Plastic Tubing

- What is thin wall plastic tubing?

- Thin wall plastic tubing is a type of hollow plastic tube characterized by a smaller wall thickness relative to its diameter. It is designed to be lightweight, flexible, and suitable for fluid transfer, insulation, and protective applications across multiple industries.

- How do I select the correct tubing size and material?

- Determine your required inner diameter, outer diameter, and wall thickness based on the flow, pressure, and compatibility needs of your application. Consult supplier datasheets or request samples for testing.

- What are the typical tolerances for thin wall tubing?

- Tolerances vary by material and manufacturing process but can range from ±0.005 to ±0.010 inches (0.127 to 0.254 mm) for high-precision extrusion and tube rolling.

- Can thin wall plastic tubing be sterilized?

- Yes. Many grades are compatible with common sterilization methods, including autoclave (steam), gamma irradiation, and ethylene oxide (EtO) gas. Confirm with your supplier based on the polymer used.

- Where can I find custom thin wall plastic tubing manufacturers?

- Use our comprehensive supplier directory to locate manufacturers offering custom extrusion, secondary processing, and industry-specific certifications.

Conclusion: Why Choose Thin Wall Plastic Tubing?

Thin wall plastic tubing offers unmatched versatility, affordability, and performance for a wide range of applications—from consumer packaging and medical devices to industrial fluid transport and electronics. With the ability to tailor materials, dimensions, and features, plastic tubing delivers solutions that meet the strictest requirements for safety, cost, and efficiency. By understanding the manufacturing processes, available grades, and supplier selection criteria outlined in this guide, you can confidently specify and source the ideal tubing for your project.

Need more information or a custom quote? Contact our experts or explore our supplier directory to start your project today.

Related searches: plastic tubing for medical devices, flexible thin wall tubing, custom plastic tube extrusion, FDA compliant tubing, clear plastic tube suppliers, best plastic tubing for chemicals, plastic tube for packaging, UV resistant plastic tubing, how to select plastic tubing, plastic tubing dimensions, plastic tubing manufacturers USA, plastic tubing applications guide, where to buy thin wall plastic tubing, compare plastic tubing suppliers, plastic vs. metal tubing, plastic tubing prices, plastic tubing chemical resistance, plastic tubing certifications.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services